Contract manufacturing in Europe is undergoing one of the most transformative phases in its history. With rapid advances in artificial intelligence, robotics, and digital twin technology, the traditional factory model is giving way to a new era of smart, interconnected, and self-optimizing manufacturing environments. These technologies are not simply improving production lines. They are redefining how manufacturers plan, monitor and deliver high-quality output with speed, precision, and cost efficiency. As competition intensifies and customer demands evolve, smart factories and Automation are becoming essential for companies that aim to lead in 2025 and beyon

The Emergence of Smart Factories and Automation

A smart factory is an environment where machine systems and digital technologies communicate seamlessly to make real-time decisions. At the heart of this model is the ability to analyze complex data, uncover patterns, and apply insights instantly. European contract manufacturers are increasingly embracing this shift as they recognize that smart factories allow them to improve operational visibility, reduce downtime, boost productivity, and deliver consistent quality. The move toward intelligent automation is also driven by labor shortages, rising production costs, and the need for rapid scalability in response to fluctuating market demands.

Artificial Intelligence as the Central Engine

Artificial intelligence is becoming the central intelligence layer in modern manufacturing. It collects data from various touchpoints such as machine sensors, inventory management systems, quality checks, and operator inputs. Once analyzed, this data enables predictive insights that optimize production in ways humans cannot achieve alone. AI helps contract manufacturers forecast demand more accurately, maintain ideal inventory levels and adjust production schedules in advance based on expected fluctuations. It also identifies bottlenecks before they disrupt operations, which significantly reduces downtime and saves costs.

In quality assurance, AI algorithms can detect defects that are too minute for the human eye. This has proved especially valuable in industries such as pharmaceuticals, electronics, and automotive, where precision determines safety and performance. By reducing variability, AI supports consistent high-quality production even when volumes change dramatically.

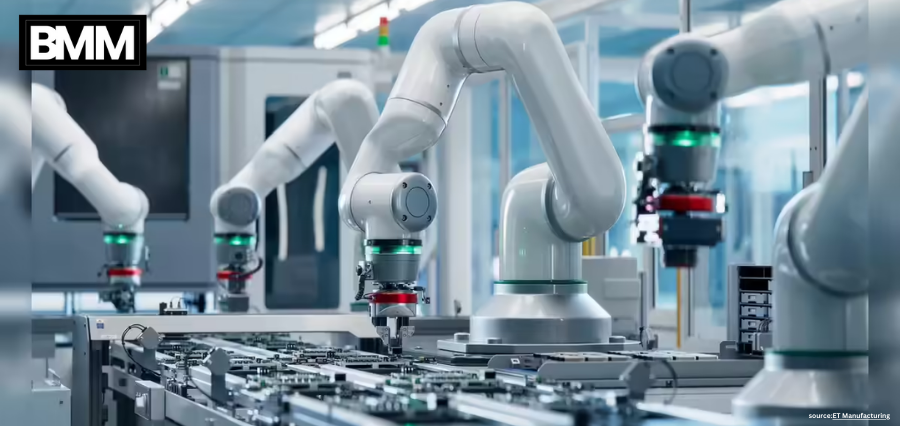

Robotics Driving Precision and Scalability

Robotics plays a crucial role in enhancing speed, accuracy, and safety on the production floor. Contract manufacturers in Europe are increasingly turning to collaborative robots, which work side by side with humans performing repetitive, high-precision, and high-risk tasks. Their ability to operate continuously without fatigue makes them crucial for maintaining shorter turnaround times and meeting tight deadlines.

Automation also allows manufacturers to scale their operations quickly. If order volumes rise, robots can take on additional tasks without requiring extensive training or new hiring cycles. This agility is especially important in sectors where product lifecycles are short and customization demands are high.

Beyond efficiency, robotics also contributes to a safer workplace. Automated systems reduce human involvement in hazardous environments and heavy lifting tasks, which helps manufacturers comply with strict European safety regulations.

Digital Twins Transforming Planning and Problem Solving

Digital twin technology is one of the most disruptive forces in contract manufacturing today. A digital twin is a virtual replica of a physical process machine or entire facility. It simulates real-world scenarios and provides accurate predictions about performance outcomes.

For manufacturers, this means they can test new layout configurations and processes before implementing them in the physical environment. Problems can be identified in the virtual model and resolved without interrupting actual production. This reduces risk significantly and shortens development cycles.

Digital twins also help manufacturers evaluate new product introductions. Instead of running costly trial batches, the simulation can predict how a new product will affect machine performance, production speed, and quality standards. This leads to stronger decision-making making improved planning, and reduced waste.

By combining digital twins with artificial intelligence, manufacturers gain a powerful tool for predicting future performance and optimizing operations continuously.

Enhanced Quality Through Intelligent Automation

Quality is one of the biggest priorities for European contract manufacturers. Smart factories equipped with sensors AI AI-powered inspection systems, and automated reporting tools maintain higher quality standards throughout the production cycle. Every step can be tracked, measured, and documented, ensuring full traceability, which is essential for regulated sectors such as medical devices and cosmetics.

Artificial intelligence helps detect inconsistencies early, while robotics ensures uniform execution of delicate processes. Digital twins further support quality by allowing manufacturers to test modifications virtually before applying them in real time. This integrated approach reduces human error and ensures each batch meets client expectations.

Efficiency Gains Across the Value Chain

The combined power of artificial intelligence, robotics, and digital twins enhances efficiency across the entire manufacturing value chain. Lead times shrink because automation streamlines production while predictive insights reduce unplanned stoppages. Energy consumption decreases as smart systems adjust usage during low activity periods. Inventory management becomes more accurate and cost-effective through data-driven forecasting.

Smart factories also facilitate smoother collaboration between manufacturers and their customers. Real-time dashboards allow clients to monitor production progress, obtain transparent quality reports, and receive updates instantly. This strengthens trust and long-term partnerships.

Conclusion

Smart factories are redefining what is possible in European contract manufacturing. Driven by artificial intelligence, robotics, and digital twins, the industry is entering a new age of speed, intelligence, and reliability. These technologies are not just enhancing operations. They are transforming the very foundation of manufacturing into a connected, intelligent system that operates with exceptional efficiency and quality. As companies prepare for 2025, this transformation will stand as one of the most defining shifts in the European industrial landscape.

Also Read :- Business Minds Media For more information